Industrial power supplies

Industrial Power Supplies

Introduction to Industrial Power Supplies

Understanding Industrial Power Supplies

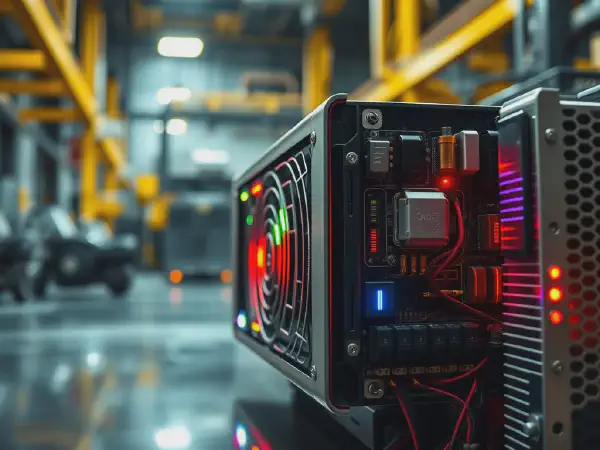

Industrial power supplies are essential electrical components that convert and regulate electrical energy to meet the specific voltage, frequency, and current requirements of various industrial applications. These power supplies ensure reliable operation of machinery, control systems, and electronic devices by transforming input electricity from sources like mains power to lower, usable voltages, such as 12 Vdc. This conversion is critical for maintaining the functionality and safety of the equipment in diverse settings, making industrial power supplies indispensable to modern operations.

The Significance of Industrial Power Supplies

The importance of industrial power supplies cannot be overstated. They play a crucial role in ensuring the efficiency and reliability of manufacturing processes, automation systems, and critical infrastructure in various industries. By providing stable power, these units help reduce the risk of equipment failure and downtime, which can lead to significant productivity losses. Moreover, high-quality industrial power supplies contribute to energy efficiency, enhancing overall operational costs through optimal energy use, protecting both the devices they power and the environment.

Types of Industrial Power Supplies

1. AC-DC Power Supplies

AC-DC power supplies are critical components in various industrial applications, converting alternating current (AC) from the mains into direct current (DC) that is usable for electronic devices and machinery. These power supplies often provide precise voltage regulation, making them suitable for sensitive equipment that requires a stable power source. Typically, they feature transformers and rectifiers to achieve the desired voltage levels and current output. The efficiency of AC-DC power supplies is vital, as higher efficiency reduces power loss as heat, thereby decreasing operational costs. Additionally, features such as noise filtering and overload protection enhance their reliability and longevity in demanding industrial environments.

2. DC-DC Converters

DC-DC converters are specialized devices designed to convert one DC voltage level to another. These converters are essential in applications where different components require varying voltage levels to function correctly. They come in various forms, including step-up (boost) or step-down (buck) converters, depending on whether the output needs to be higher or lower than the input voltage. Engineering DC-DC converters requires careful consideration of factors like efficiency, power density, and thermal management to ensure optimal performance in space-constrained environments. With their compact size and high efficiency, DC-DC converters are widely used in portable devices, renewable energy systems, and automotive applications.

3. Switch Mode Power Supplies (SMPS)

Switch Mode Power Supplies (SMPS) have gained popularity in industrial applications due to their high efficiency and versatility. These power supplies operate by rapidly switching the input voltage on and off, reducing energy loss and resulting in a lightweight and compact design. The ability of SMPS to operate across a wide range of input voltages makes them ideal for global applications. They are commonly used in situations where weight and size are critical, such as in telecommunications and computer systems. Furthermore, modern SMPS designs focus on improving efficiency and reducing electromagnetic interference (EMI), ensuring compliant and reliable performance in sensitive environments.

| Industrial Power Supplies Types | Voltage Regulation | Efficiency Ratings | Noise & Ripple Levels | Cooling Methods | Applications |

|---|---|---|---|---|---|

| AC-DC Power Supply | Maintains steady voltage | High efficiency options | Minimal interference | Passive and active cooling | Robotics and automation |

| DIN Rail Power Supply | Stabilizes output | 85% to 95% efficiency | Low noise operations | Heat sinks | Industrial control systems |

| Bench Power Supply | Regulates voltage | Variable efficiency | Medium noise levels | Cooling fans | Laboratory equipment |

| Panel Mount Power Supply | Voltage stabilizing | Wide range efficiency | Ripple control implemented | Air-cooled | Enclosures and protective devices |

| Switch Mode Power Supply | Precise voltage output | Above 90% efficiency | Low ripple designs | Modern thermal solutions | Telecommunications |

| Unregulated Power Supply | Fluctuating output | Lower efficiency | High ripple potential | Minimal cooling | Hobbyist electronics |

| Linear Power Supply | Consistent voltage | Moderate efficiency | Low noise, high ripple | Large heat sinks | Audio equipment and fine-tuned devices |

Essential Characteristics of Industrial Power Supplies

Stable Output Voltage Control

Voltage regulation is a crucial feature of industrial power supplies, ensuring the output voltage remains stable despite variations in load or input voltage. This stability is vital for maintaining the performance and longevity of electronic devices, preventing damage caused by voltage fluctuations during operation.

High Efficiency Ratings

Efficiency ratings indicate the percentage of input power that is effectively converted into usable output power. A higher efficiency rating signifies reduced energy loss, resulting in lower operational costs and decreased heat generation. This characteristic is essential not only for cost savings but also for enhancing the power supply's lifespan.

Minimal Noise and Ripple Levels

Noise and ripple levels are critical aspects of power supply performance. Low noise and ripple are necessary to maintain the purity of the output power, ensuring that electronic devices operate without interference from electrical noise. High-quality industrial power supplies are designed to minimize these unwanted fluctuations, protecting sensitive electronics from potential disruptions.

Robust Overload and Short-Circuit Protection

Overload and short-circuit protection are essential safety features in industrial power supplies. This protection prevents damage to both the power supply and connected devices during overload conditions or short circuits. By incorporating these safeguards, industrial power supplies enhance reliability and ensure the safety of the overall electrical system.

Selecting the Right Power Supply

Aligning Power Supply Specifications to Your Needs

When choosing a power supply, it's essential to ensure that its specifications match the requirements of your application. Start by determining the necessary input voltage, output voltage, and current ratings. Power supply units (PSUs) come in various configurations, from AC-DC adapters to switch-mode supplies, catering to different voltage needs. An efficient power supply must convert mains electricity to usable output while providing stable voltage levels to prevent device damage.

Efficiency ratings are also critical; higher ratings denote less energy lost as heat, reducing operational costs and environmental impact. Additionally, consider the Mean Time Between Failures (MTBF) to gauge reliability—higher MTBF values indicate longer lifespans, crucial for applications where uptime is vital. Choosing a PSU with appropriate specifications ensures optimal performance, safety, and longevity for your devices.

Evaluating Environmental and Operational Conditions

In addition to matching specifications, considering the environmental conditions in which the power supply will operate is key. Factors such as temperature, humidity, and potential exposure to dust or moisture can significantly impact a power supply's performance and durability.

For instance, industrial settings may require ruggedized units that can withstand harsher conditions, while desktop applications may necessitate quieter operation and a smaller footprint. Power supply cooling methods are also important; assess whether your application will benefit from passive or active cooling solutions to manage heat effectively. Ensuring your power supply is suited to its operating environment will enhance its reliability and efficiency.

Applications of Industrial Power Supplies

Automation and Robotics

Industrial power supplies are essential in automation and robotics, powering control systems that drive robotic machinery. These power units ensure that robots operate smoothly and reliably, providing the necessary electrical energy to perform precise manufacturing tasks. With features such as voltage regulation and overload protection, these power supplies support the growing need for automation across various industries, enhancing productivity and efficiency.

Process Control Applications

In process control applications, industrial power supplies play a critical role in regulating power for machinery that is involved in mixing, cooking, or transforming products chemically. By delivering stable and consistent electrical energy, these power supplies help maintain the quality of the production process, reduce downtime, and ensure that operations run efficiently. Without reliable power supplies, manufacturing consistency and product quality could be compromised.

Energy and Utility Management

Industrial power supplies are a cornerstone in energy and utility management, providing stable power for monitoring and controlling energy production and distribution systems. These power units support critical infrastructure by ensuring that the equipment operates reliably, promoting energy efficiency, and contributing to effective grid management. In an era where energy conservation is paramount, robust power supplies are indispensable in managing these systems effectively.

Intralogistics and Automated Warehousing

In the realm of intralogistics and automated warehousing, industrial power supplies facilitate the effective operation of equipment such as conveyor belts and sorting systems. By providing dependable power, these supplies help streamline warehouse processes, improve throughput, and enhance overall operational efficiency. In such high-paced environments, reliable power is crucial for maintaining smooth logistics and reducing operational bottlenecks.

Conclusion

Selecting a Reliable Supplier: Key Takeaways

Choosing a reliable supplier for your power supply needs is crucial for ensuring performance and safety in your applications. A trusted supplier, like RS, offers a diverse range of power supply units that meet varying industry requirements, facilitating optimal performance across different scenarios.

Reliability is not just about quality equipment; it encapsulates the support and expertise provided during the purchasing process. Suppliers who prioritize customer service and offer comprehensive product knowledge enhance your purchasing experience and ensure you make informed decisions. Furthermore, a reputable supplier is a constant source of innovation, regularly updating their product lines to include the latest technologies, which can significantly benefit your operations in terms of efficiency and cost-effectiveness.

By investing in power supplies from a dependable supplier, you safeguard your projects against downtime and adversity, ensuring an uninterrupted power supply essential for success in a rapidly evolving technological landscape.

Frequently Asked Questions about Power Supplies

What are the benefits of using Switch Mode Power Supplies (SMPS)?

Switch mode power supplies (SMPS) offer several advantages, including high efficiency, compact size, and adjustable output voltages. They are adept at handling varying loads, which makes them suitable for a wide array of applications in both consumer electronics and industrial settings.

How do I determine the required voltage for my power supply?

To determine the required voltage for your power supply, first check the specifications of the device you wish to power. Look for the recommended voltage rating, typically indicated in volts (V). Ensure the power supply matches this voltage to prevent damage, while also considering any peak or inrush current specifications.

What is the difference between Switch Mode Power Supplies (SMPS) and Linear Power Supplies?

Switch Mode Power Supplies (SMPS) convert main AC power to high-frequency AC and then back to DC. They are known for their efficiency, often exceeding 80-90%, and can deliver stable output under varying load conditions. In contrast, Linear Power Supplies provide a consistent output by using a transistor circuit to regulate voltage but are generally less efficient and generate more heat due to energy dissipation in the regulation process. Ultimately, SMPS are preferred for applications needing efficiency and compact designs, while linear supplies are favored in situations where low noise and stability are critical.

How can overload protection enhance power supply safety?

Overload protection is a critical safety feature that helps prevent damage to the power supply and connected devices. In cases of excessive load, the protection circuit activates, shutting down the output or limiting the current flow. This functionality safeguards your equipment from overheating, component failure, and potential fire hazards, ensuring reliable and safe operation in various applications.